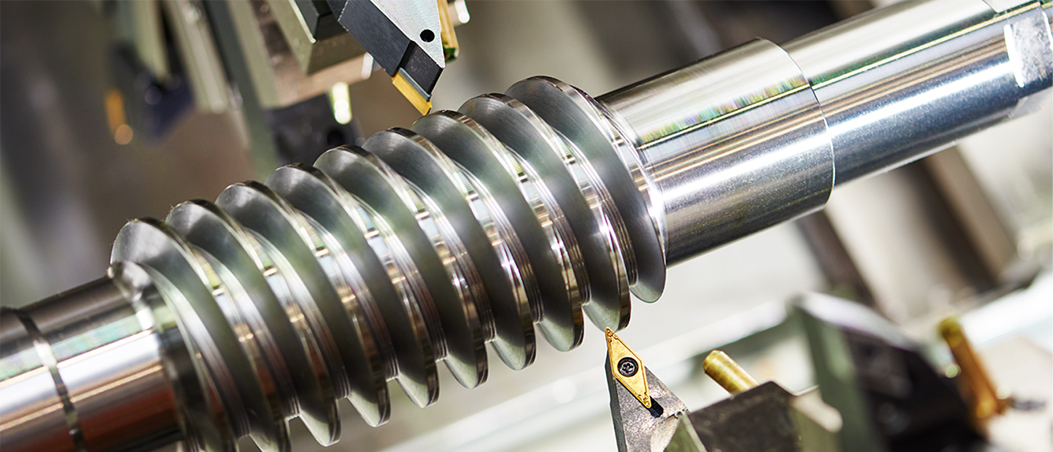

How to distinguish the use of end milling cutters with different helix angles?

2021-12-28 Share Views 743

The spiral Angle of end milling cutter can be divided into 30º · 45º · 50° and so on. Now let's talk about how to distinguish them.

1. The role of spiral Angle

The larger the helical Angle of end milling cutter, the longer the contact length between workpiece and cutting edge. This reduces the load on the cutting edge per unit length, thus extending tool life. At the same time, however, the cutting resistance will increase, so the use of high clamping rigidity of the handle must be considered.

Small spiral Angle end milling cutter: long cutting edge (blue line part length) short

2. Selection of spiral Angle

For stainless steel materials with low thermal conductivity and great influence on blade tip heat, the use of large spiral Angle end milling cutter is helpful to prolong tool life. In addition, the characteristics of the finished surface change due to the helix Angle. For example, when smooth finishing is required, large spiral Angle end mills can sometimes be used. However, the use of large spiral Angle type end milling cutter, cutting resistance will increase, right spiral Angle tool out of the force will become larger, so we must take corresponding measures, such as the use of clamping high rigidity of the handle. Although the rigidity of the tool can be ensured, small spiral Angle end mills are sometimes used when the workpiece rigidity is low, such as thin plate machining.

3. End milling cutter for finishing of large spiral side with spiral Angle of 50° :

Adopt multi - edge design, the cutter rigidity is good, can reduce the amount of cutting tool when cutting side to the greatest extent.

The blade tip is protected by the tip Angle, which can restrain the blade tip from breaking to the maximum extent.

4. Suitable for SUS304 and other difficult cutting materials high speed cutting 60° spiral Angle end milling cutter:

For hard cutting materials with low thermal conductivity and edge temperature rising easily during cutting, the unique blade shape can restrain the influence of cutting heat on edge.

5. High efficiency roughing end milling cutter for high speed machining:

The use of 45° spiral Angle and unique groove shape, while achieving high speed machining and high wear resistance. Using fine tooth grain chip breaker, the surface roughness is good after processing. ALC coating with excellent lubricity and good heat resistance (1100℃) is adopted.

4000-400-654

4000-400-654